Yuav muaj qhov tsis xws luag hauv txhua qhov casting.Lub hav zoov ntawm cov teeb meem no yuav ua rau muaj kev phom sij loj heev rau qhov zoo ntawm qhov casting.Kev kho vuam kom tshem tawm cov kev tsis zoo no hauv cov txheej txheem tsim khoom kuj yuav coj lub nra hnyav rau cov txheej txheem ntau lawm..Tshwj xeeb, raws li lub valve yog nyias-plhaub casting uas raug rau siab thiab kub, lub compactness ntawm nws sab hauv yog ib qho tseem ceeb heev.Yog li ntawd, qhov tsis xws luag sab hauv ntawm castings dhau los ua qhov kev txiav txim siab cuam tshuam rau qhov zoo ntawm castings.

Internal tsis xws luag ntawm valve castings mas muaj xws li pores, slag inclusions, shrinkage porosity thiab tawg.

Ntawm no yuav qhia txog ib qho ntawm qhov tsis xws luag ---- Qhov pores thiab shrinkage porosity

(1) Pores:

Pores yog tsim los ntawm cov pa roj, qhov chaw ntawm lub qhov yog du, thiab nws yog generated nyob rau hauv los yog ze ntawm lub casting, thiab cov duab yog feem ntau ncig los yog oval.

Lub ntsiab qhov chaw ntawm cov pa uas tsim pores yog:

① Cov nitrogen thiab hydrogen yaj nyob rau hauv cov hlau yog muaj nyob rau hauv cov hlau thaum lub sij hawm solidification ntawm lub casting, tsim ib tug kaw ncig los yog oval puab phab ntsa nrog metallic luster pores.

②Moisture los yog volatile tshuaj nyob rau hauv cov qauv khoom yuav dhau los ua roj vim cua sov, tsim pores nrog tsaus xim av sab hauv phab ntsa.

③ Thaum lub sij hawm pouring txheej txheem ntawm cov hlau, vim qhov tsis ruaj tsis khov, cov huab cua tau koom nrog tsim cov pores.

Yuav ua li cas tiv thaiv Pores tsis xws luag:

① Hauv smelting, siv tsawg los yog tsis muaj xeb hlau cov ntaub ntawv raw li ua tau, thiab ci thiab qhuav cov cuab yeej thiab ladle.

② Cov hlau molten yuav tsum tau muab tso rau ntawm qhov kub thiab txias ntawm qhov kub thiab txias, thiab cov hlau molten yuav tsum tau ua kom zoo kom ua kom lub zog ntawm cov pa.

③ Tus txheej txheem tsim ntawm lub ncuav riser yuav tsum ua kom lub taub hau siab ntawm cov hlau molten kom tsis txhob muaj kev cuam tshuam cov pa roj, thiab teeb tsa txoj hauv kev rau cov pa tsim nyog.

④ Cov khoom siv molding yuav tsum tswj cov dej cov ntsiab lus thiab cov roj tsim, ua kom cov huab cua permeability, thiab cov xuab zeb pwm thiab cov xuab zeb core yuav tsum tau ci thiab qhuav kom ntau li ntau tau.

(2) Shrinkage kab noj hniav (xoo):

Nws yog ib qho kev sib txuas los yog tsis sib txuas los yog cov kab noj hniav tsis sib xws (kab noj hniav) hauv qhov casting (tshwj xeeb tshaj yog ntawm cov kub sib koom), nrog rau qhov ntxhib hauv qhov chaw thiab xim tsaus.Cov nplej yog ntxhib, feem ntau dendrites, thiab sib sau ua ke hauv ib lossis ntau qhov chaw, thiab cov dej xau tau yooj yim tshwm sim thaum lub sijhawm ntsuas hydraulic.

Yog vim li cas rau lub shrinkage kab noj hniav (xoo):

lub ntim shrinks thaum cov hlau yog solidified los ntawm ib tug kua lub xeev mus rau ib tug khoom lub xeev.Lub shrinkage kab noj hniav ntawm cov hlau castings yeej yog tshwm sim los ntawm kev tswj tsis raug ntawm cov txheej txheem sib lawv liag, uas tej zaum yuav tshwm sim los ntawm qhov teeb tsa tsis raug, qhov kub siab ntawm molten steel pouring, thiab loj hlau shrinkage.

Txoj kev los tiv thaiv shrinkage kab noj hniav (loo):

① Kev tshawb fawb tsim cov txheej txheem casting kom cov hlau molten tuaj yeem ua kom muaj zog, thiab thawj qhov khoom yuav tsum tau ntxiv los ntawm cov hlau molten.

② Ua kom raug thiab tsim nyog tsim cov risers, nyiaj pab, thiab cov hlau txias sab hauv thiab sab nraud kom ntseeg tau tias muaj kev sib koom ua ke.

③ Thaum pouring molten steel, thaum kawg pouring los ntawm sab saum toj ntawm lub riser yog tsim nyog los xyuas kom meej qhov kub thiab txias ntawm cov hlau molten, thiab txo cov tiam ntawm shrinkage qhov.

④ Nyob rau hauv cov nqe lus ntawm pouring ceev, low-speed pouring yog ntau conducive rau sequential solidification dua high-speed pouring.

⑤ Cov dej kub yuav tsum tsis txhob siab dhau.Cov hlau molten yog tso tawm ntawm qhov kub thiab txias thiab nchuav tom qab sedation, uas yog qhov tsim nyog los txo qis cov kab noj hniav.

Tsis-rov qab kuaj xyuas valve

Lub rooj vag valveyog cov feem ntau hom kos li qub thiab nquag siv los tswj cov kab rov tav ntws.

Cov kua dej siab qhib lub disc kom tso dej los yog roj.

Tom qab qhov ntws nres, lub disc tig rov qab mus rau hauv nws txoj haujlwm kaw, so tawm tsam lub rooj zaum ntawm lub valve thiab tiv thaiv kev rov qab los.

Lub siab ntawm txhua qhov rov qab ntws kuj ua haujlwm kaw lub disc.

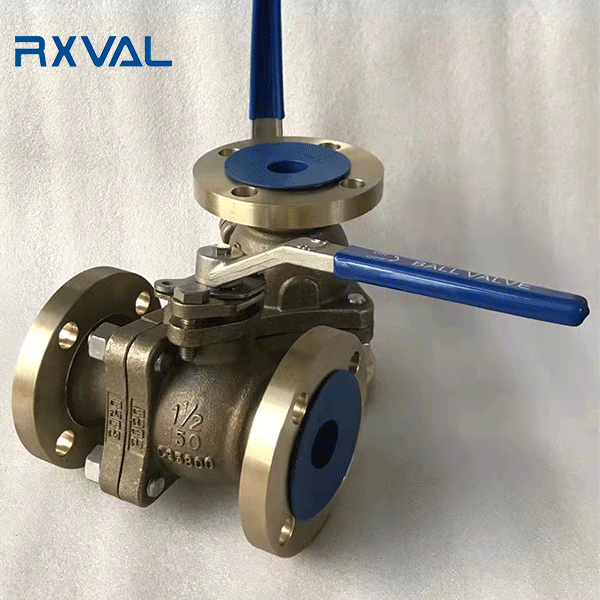

NICKEL ALUMINIUM BRONZE BALL VALVE C95800 150LB FLANGED kawg

Flanged Ball Valves ua los ntawm C95800 Nickel Aluminium Bronze (NAB) rau qhov xav tau tshaj plaws, tshwj xeeb tshaj yog tsim rau cov dej hiav txwv.RXVAL Valves muaj ntau yam ntawm ntab thiab trunnion pob li qub, los ntawm cov qauv siv rau qhov kub thiab txias.Xaiv koj cov khoom siv lub cev, xaus kev sib txuas thiab txiav rau koj qhov xav tau hauv chav kawm & qhov loj me lossis peb tuaj yeem pab koj xaiv cov ntaub ntawv zoo raws li koj cov txheej txheem txheej txheem.

THREADED/ScrewED GLOBE VALVE 200WOG

Cov neeg siv khoom muaj cov cai tshwj xeeb rau cov khoom thiab yuav tsum muab cov lus qhia hauv qab no hauv daim ntawv cog lus:

1. Xim Xim

2.Confirmed kos npe nrog kos npe thiab stamp

3.Service nruab nrab, kub thiab siab ntau yam

4.Inspection qauv thiab lwm yam yuav tsum tau xws li 3rd tog soj ntsuam.

5. Qhia qhov yuav tsum tau muaj rau lub logo cam khwb cia ntawm lub valve.

6. Qhia qhov yuav tsum tau ua ntawm lub logo ntawm lub Lever.Los yog daim ntawv lo qauv.

7. Qhia Yog tias muaj kev tshwj xeeb rau pob.

Npaj kom paub ntxiv?Pib hnub no!

Post lub sij hawm: Aug-06-2022